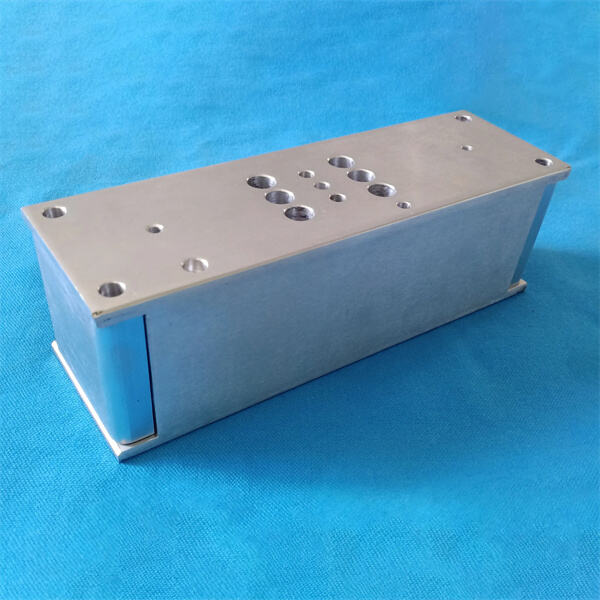

O dispositivo especializado que é essencial para manter o fluxo de ar dentro do sistema é uma assembleia de válvula de ar. Isso é especialmente crítico em regiões onde a altitude varia, como ao subir uma montanha ou descer para um vale. Quando muito alto, a assembleia permite que parte do ar escape. Isso é para garantir que tudo funcione de forma suave e segura. A assembleia de válvula de ar contém um corpo, uma válvula, um diafragma e uma tampa. Cada peça que você vê tem um papel específico que ajuda a assembleia a funcionar.

Leia abaixo para ver como uma válvula de ar quebrada ou com defeito pode criar muitos problemas no sistema. Por exemplo, se a válvula não funcionar corretamente, ela pode permitir que demasiado ar se acumule, causando problemas de pressão que podem levar a situações perigosas. Se o diafragma ficar rasgado ou danificado, a montagem deixará de funcionar também. O resultado pode ser vazamentos ou outros problemas difíceis de resolver. Problemas no PC podem ser altamente irritantes, especialmente quando você quer que o sistema funcione corretamente. Válvulas de ar de qualidade ajudam a prevenir problemas como esses. Muitos desses problemas podem ser evitados com uma boa montagem.

Montar a peça não é muito complicado, mas é crucial garantir que seja feito corretamente para evitar complicações futuras. O primeiro passo é garantir que você tenha todas as peças e ferramentas necessárias antes de começar. Isso permite que o processo ocorra sem problemas. Em seguida, basta seguir pacientemente as instruções passo a passo para montagem. É fundamental prestar atenção em como os diferentes componentes se conectam. Erros de instalação podem ser tortuosos de corrigir posteriormente. Depois que a montagem estiver instalada, a verificação periódica e a manutenção são de paramount importância. Isso envolve verificar sinais de desgaste ou dano que possam indicar que ela não está funcionando corretamente mais. A manutenção pode identificar pequenos problemas antes que eles se tornem grandes.

Alguns problemas comuns que podem ocorrer em uma montagem de válvula de ar incluem o seguinte; tornar-se ciente deles pode ajudá-lo a solucionar os problemas rapidamente. Um dos problemas mais frequentes é o vazamento, geralmente devido a um diafragma danificado. Se você experimentar qualquer vazamento, pode resolver esse problema simplesmente trocando o diafragma. Normalmente, isso é uma solução simples e rápida. Da mesma forma, se a válvula estiver defeituosa, ela pode precisar ser substituída por completo. A falta de manutenção também pode causar outros problemas, como entupimentos ou obstruções ao longo do sistema, e um ajuste correto é essencial. Esses entupimentos podem impedir que o fluxo de ar funcione corretamente, o que pode levar a outros problemas no futuro. Um funcionamento adequado e eficiente da montagem da válvula de ar é muito necessário para evitar todos esses problemas, portanto, é altamente recomendável realizar inspeções e manutenções periódicas na montagem da válvula de ar.

Uma atualização do conjunto da válvula de ar pode melhorar significativamente o desempenho e a eficiência do seu sistema. Com isso, você pode ajustar como ele funciona -- seja usando uma válvula melhor, ou utilizando materiais melhores no conjunto. Uma atualização também pode servir para mitigar problemas como vazamentos ou outras questões devido a um conjunto defeituoso. Se você decidir substituir o conjunto da válvula de ar, certifique-se de realizar pesquisas para fazer uma compra informada de um produto bem construído de uma empresa renomada, como a Shanghai Chongfu. Embora o custo inicial possa ser alto, você economizará tempo e dinheiro, pois será menos provável que precise fazer reparos futuros.

A Shanghai Chongfu Industry Co., Ltd. oferece preços agressivos enquanto mantém a qualidade do produto. A empresa oferece tempos curtos de envio e entrega, tornando-a uma escolha confiável para clientes que precisam de prazos rápidos. Além disso, eles garantem uma inspeção e teste minuciosos de todos os produtos antes do embarque, garantindo que os clientes recebam produtos em perfeitas condições.

A Shanghai Chongfu Industry Co., Ltd. oferece uma ampla gama de bombas de diafragma e acessórios, incluindo peças para marcas renomadas mundialmente, como Wilden, Sandpiper, Almatec, Yamada, Graco, Blagdon e Veresmatic. Seu catálogo de produtos inclui diafragmas, assentos de válvula, válvulas esféricas, conjuntos de válvulas de ar, corpos centrais, carcaças, coletores, eixos, silenciadores e kits de reparação, proporcionando aos clientes uma seleção abrangente de peças e bombas para diversas necessidades industriais.

Com mais de 13 anos de experiência no setor de bombas de diafragma, a empresa desenvolveu extensa expertise na venda de peças de bombas AODD (Air Operated Double Diaphragm). Eles se especializam em oferecer componentes de bombas de alta qualidade e confiáveis, garantindo que seus produtos atendam aos padrões da indústria e superem as expectativas dos clientes.

A empresa utiliza matérias-primas de primeira linha, como o PTFE DuPont americano, 3M (DYGON) e Daikin do Japão, para fornecer seus diafragmas. Isso garante uma qualidade estável e excelente que atende ou supera os padrões da indústria. A empresa trabalha de perto com fabricantes confiáveis que empregam equipamentos de produção avançados e instrumentos de teste rigorosos, permitindo um controle de qualidade preciso em toda a cadeia de suprimentos.

Direitos autorais © Shanghai Chongfu Industry Co., Ltd. Todos os direitos reservados