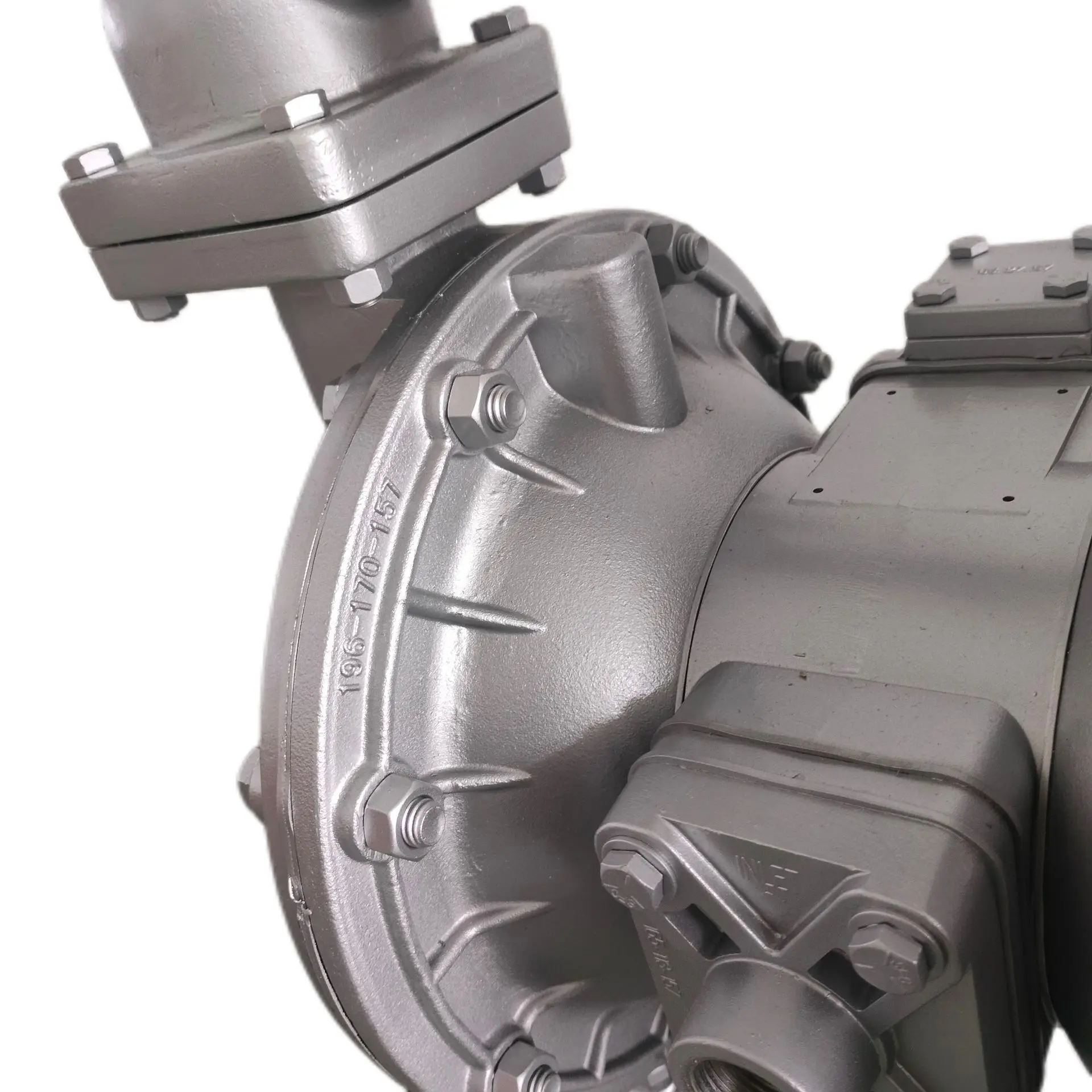

Sandpiper 1.5'' Stainless Steel S15B1SGTABS100 Double Pneumatic Diaphragm Pump with PTFE Diaphragm

- Introduction

Introduction

Air-Operated Diaphragm Pump

Material:

Wetted Material:Aluminum、Stainless steel、Cast Iron

Non-Wetted Material:Aluminum

Diaphragm Materials:EPDM、FKM、Hytrel、Neoprene、BUNA、Santoprene、PTFE

Non-Wetted Material:Aluminum

Diaphragm Materials:EPDM、FKM、Hytrel、Neoprene、BUNA、Santoprene、PTFE

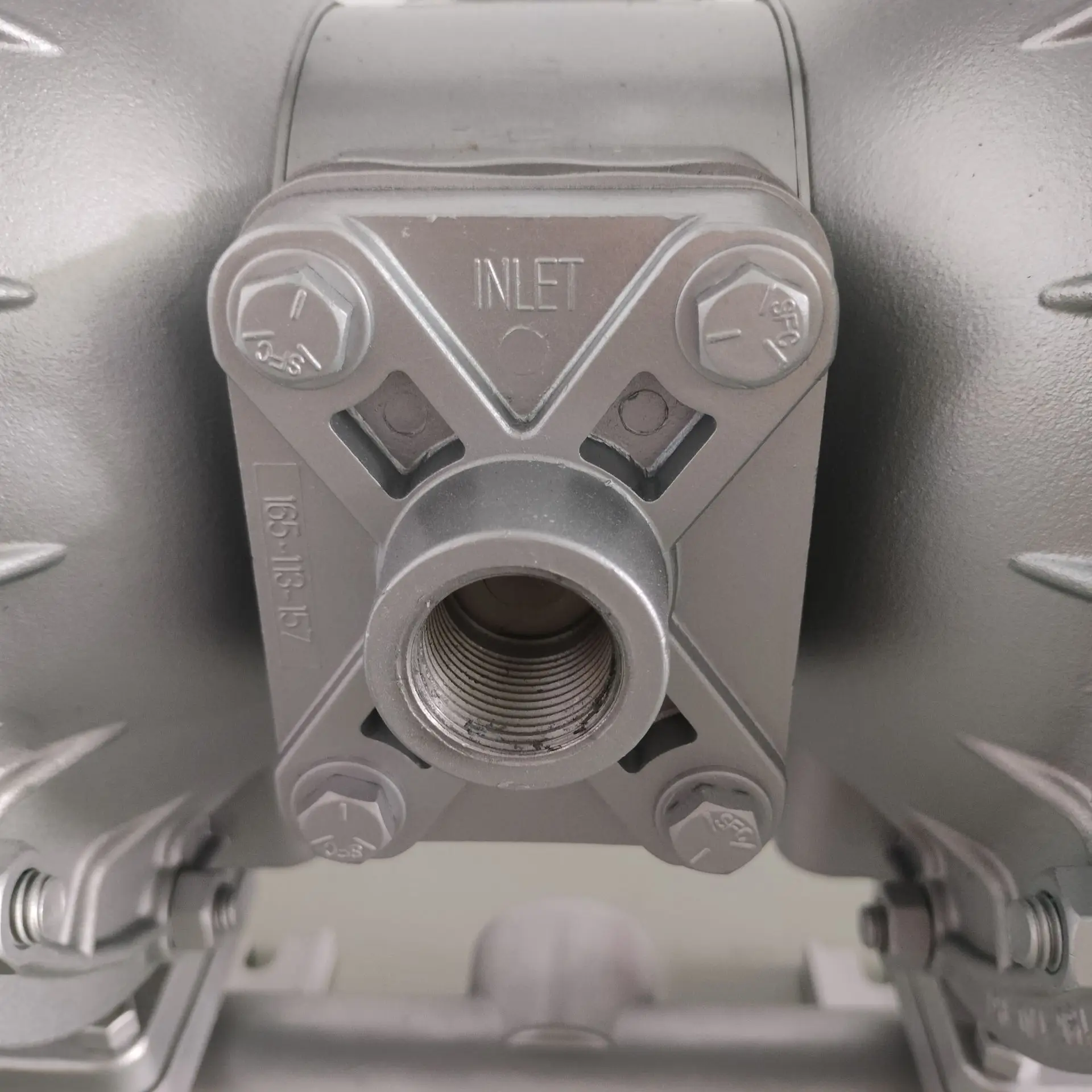

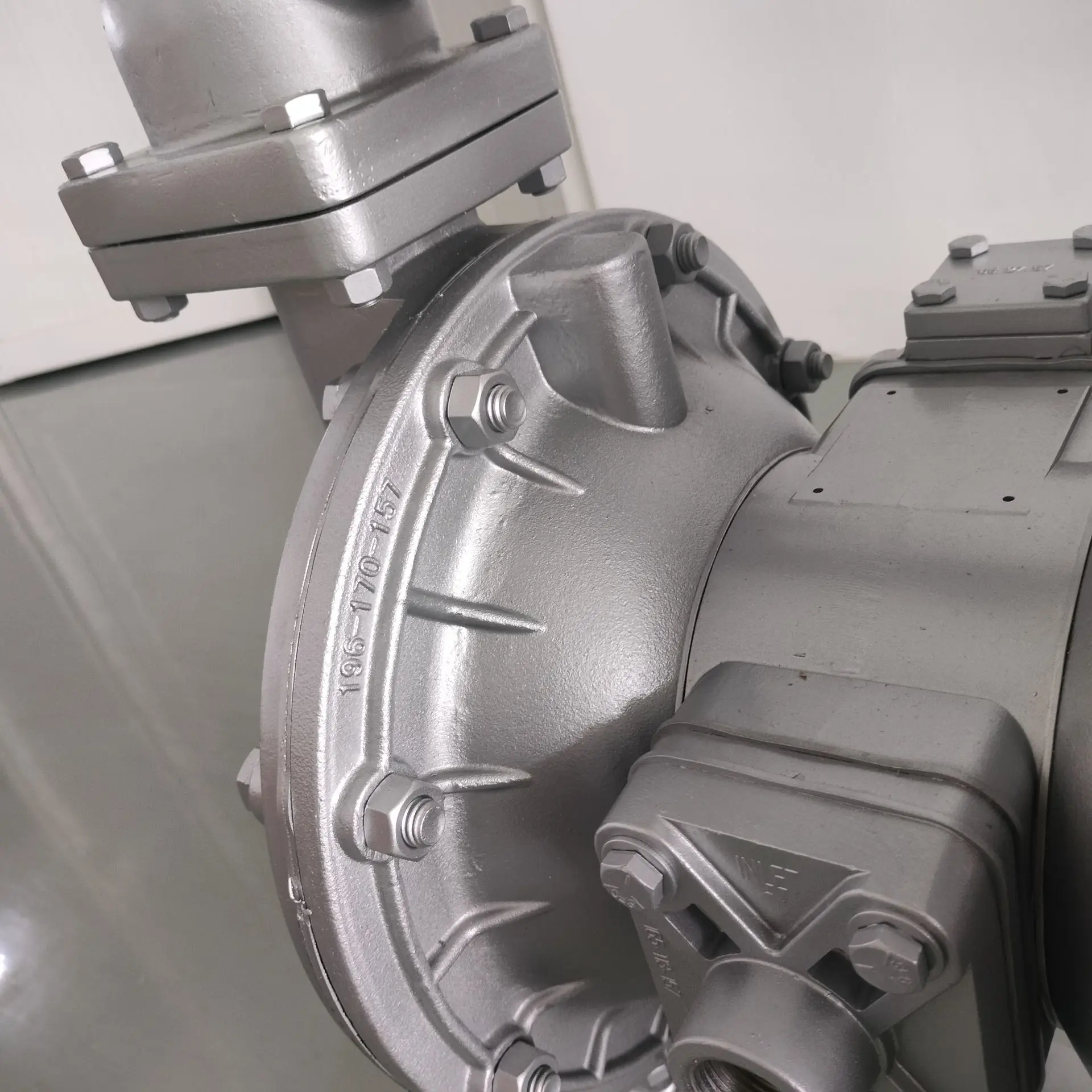

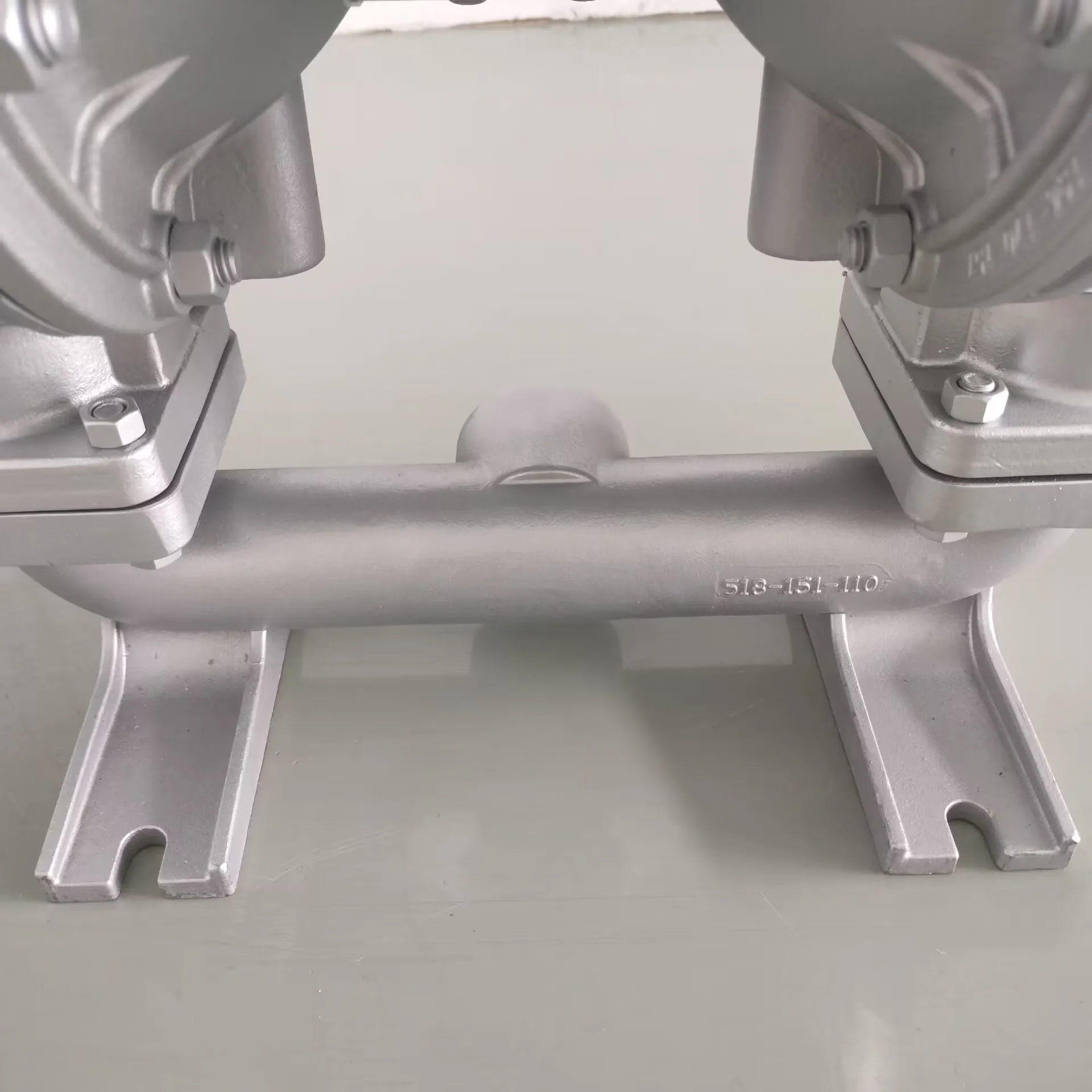

Details Images

Product display

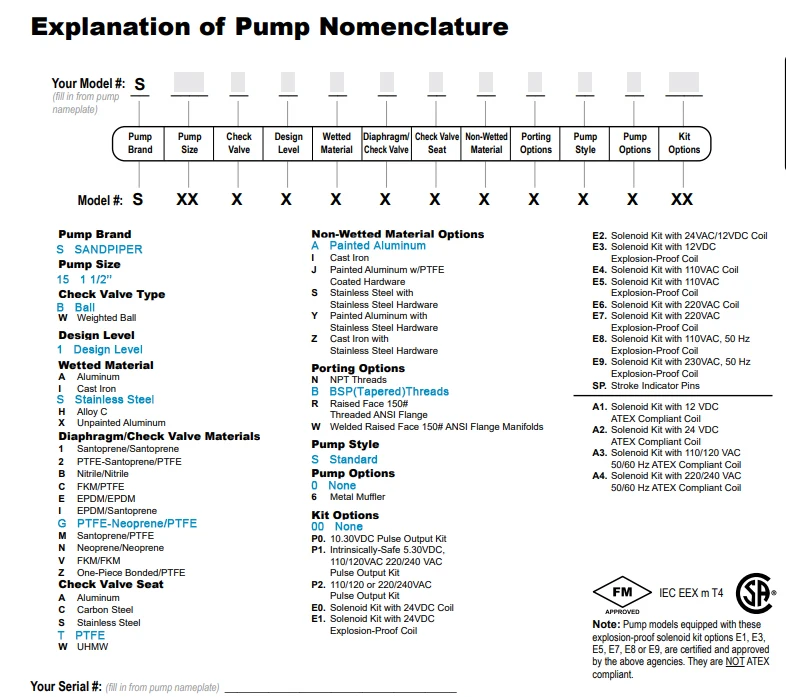

MODEL |

S15B1SGTABS000 |

BRAND |

Chongfu |

Shell material |

316 stainless steel |

Diaphragm material |

ptfe diaphragm |

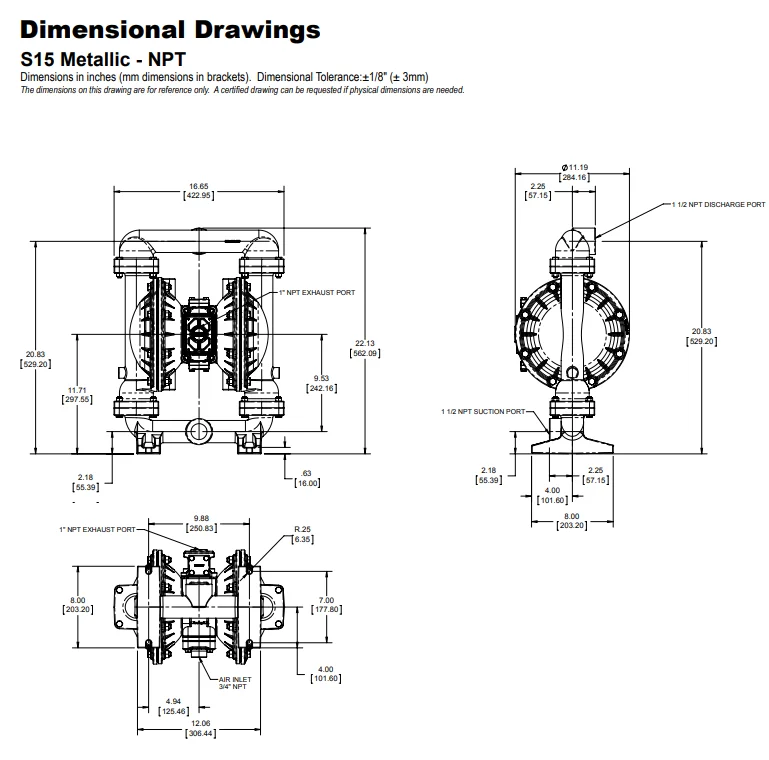

Medium outlet size |

1-1/2'' |

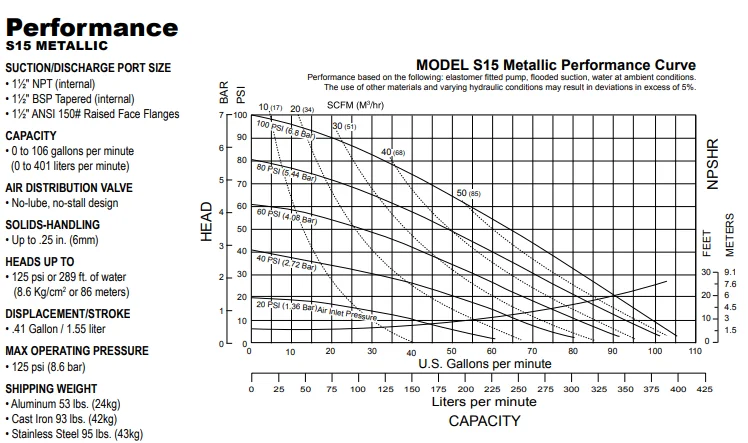

Max Flow |

0 to 106 gallons per minute (0 to 401 LPM) |

Max Pressure |

125 psi (8.6 bar) metallic center |

Pneumatic Diaphragm Pump Advantages:

The SANDPIPER 1½" S15 Metallic AODD Pump provides superior suction lift of greater than 22 ft (6.7 m). Designed for outstanding operation, this versatile and mobile pump is perfect for OEM applications.

Equipped to handle abrasive fluids and suspended solids, it gives exceptional performance in harsh chemical applications where reliability is critical. Additionally, this AODD pump offers air-side interchangeability with SANDPIPER’s S20 and S30 pumps for ease of inventory management and reduced inventory costs.

The durable, bolted construction of the S15 is superior to the clamp-band construction pump, providing excellent leak-free performance. Material of construction options include: aluminum, cast iron and stainless steel with elastomer TPE (thermoplastic elastomers) and PTFE options in diaphragms and check valves.

S15 FEATURES Serviceability: The air distribution system (ADS) is one of the most frequently serviced parts of any AODD pump. Only SANDPIPER's ESADS+ feature allows access to the complete ADS without removing the pump from service. Repair or clean in five minutes (versus 55 minutes for competitors).

Simplicity: SANDPIPER’S original ADS is fully interchangeable, repairable and inline-serviceable. Other manufacturers frequently change ADS designs, creating issues with interchangeability, obsolete inventory and increased cost of ownership.

The durable, bolted construction of the S15 is superior to the clamp-band construction pump, providing excellent leak-free performance. Material of construction options include: aluminum, cast iron and stainless steel with elastomer TPE (thermoplastic elastomers) and PTFE options in diaphragms and check valves.

S15 FEATURES Serviceability: The air distribution system (ADS) is one of the most frequently serviced parts of any AODD pump. Only SANDPIPER's ESADS+ feature allows access to the complete ADS without removing the pump from service. Repair or clean in five minutes (versus 55 minutes for competitors).

Simplicity: SANDPIPER’S original ADS is fully interchangeable, repairable and inline-serviceable. Other manufacturers frequently change ADS designs, creating issues with interchangeability, obsolete inventory and increased cost of ownership.

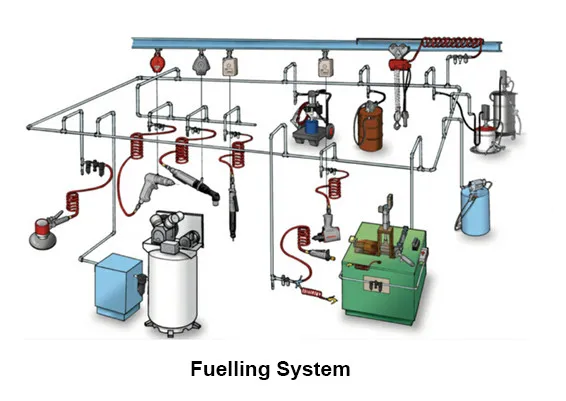

air-driven diaphragm pumps Widely used in the transport of diesel, petrol, gear oil, hydraulic oil ,etc .Can effectively carry and distribute lubricant oils to machinery as part of an automatic lubrication system.

can deal with all kinds of corrosive, volatile, flammable, poisonous fluids with particles and high viscosity.

1.The pump can suck the peanut, pickles, tomato slurry, red sausage, chocolate, hops and syrup etc.

2. The pump can suck the paint, pigment, glue and adhesive etc.

3. The pump can suck various glazed slurries of tile, porcelain, brick and chinaware etc.

4. The pump can suck various grinding materials, corrosive agent and clean the oil dirt etc.

5. The pump can suck various toxin and flammable or volatility liquid etc.

6. The pump can suck various wedge water, cement slurry and mortar etc.

7. The pump can suck various strong acid, alkali and corrosive liquid etc.

8. It can be used as a front-step tranmission device of the solid and liquid separation equipment.

2. The pump can suck the paint, pigment, glue and adhesive etc.

3. The pump can suck various glazed slurries of tile, porcelain, brick and chinaware etc.

4. The pump can suck various grinding materials, corrosive agent and clean the oil dirt etc.

5. The pump can suck various toxin and flammable or volatility liquid etc.

6. The pump can suck various wedge water, cement slurry and mortar etc.

7. The pump can suck various strong acid, alkali and corrosive liquid etc.

8. It can be used as a front-step tranmission device of the solid and liquid separation equipment.

Air-Operated Diaphragm Pump Installation

pumps are suitable for an endless variety of applications . Our pumps can be deployed in fixed installations within a process flowsystem, or used as portable or mobile units that can be transported to where it is to be used.

Pump, self-priming

pumps are dry self-priming. Depending on the pump specification a suction lift of up to 8 m

pumps are dry self-priming. Depending on the pump specification a suction lift of up to 8 m

Pump with positive suction

Depending on the pump type, the suction side inlet pressure may need to be limited to a max. pressure

Depending on the pump type, the suction side inlet pressure may need to be limited to a max. pressure

Pump, submerged

pumps can be totally submerged in the pumped medium. The exhaust outlet must remain above the fluid level.

pumps can be totally submerged in the pumped medium. The exhaust outlet must remain above the fluid level.

Pump for drums

pumps can be directly mounted on drums or containers.

pumps can be directly mounted on drums or containers.

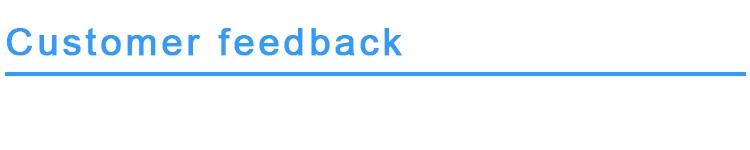

Our Exhibition

OUR CERTIFICATES

FAQ

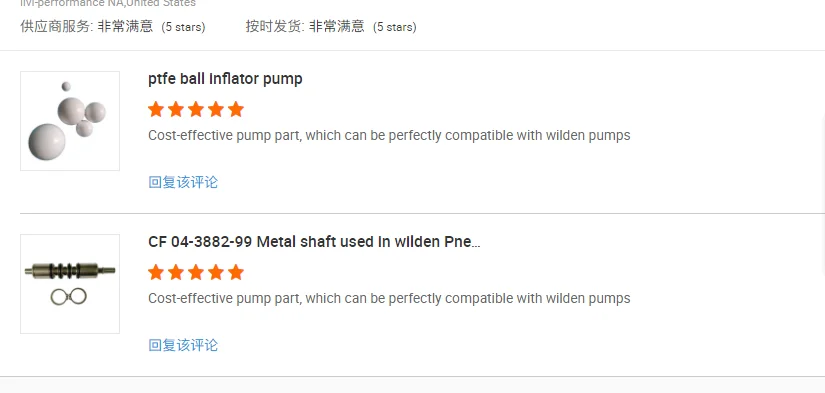

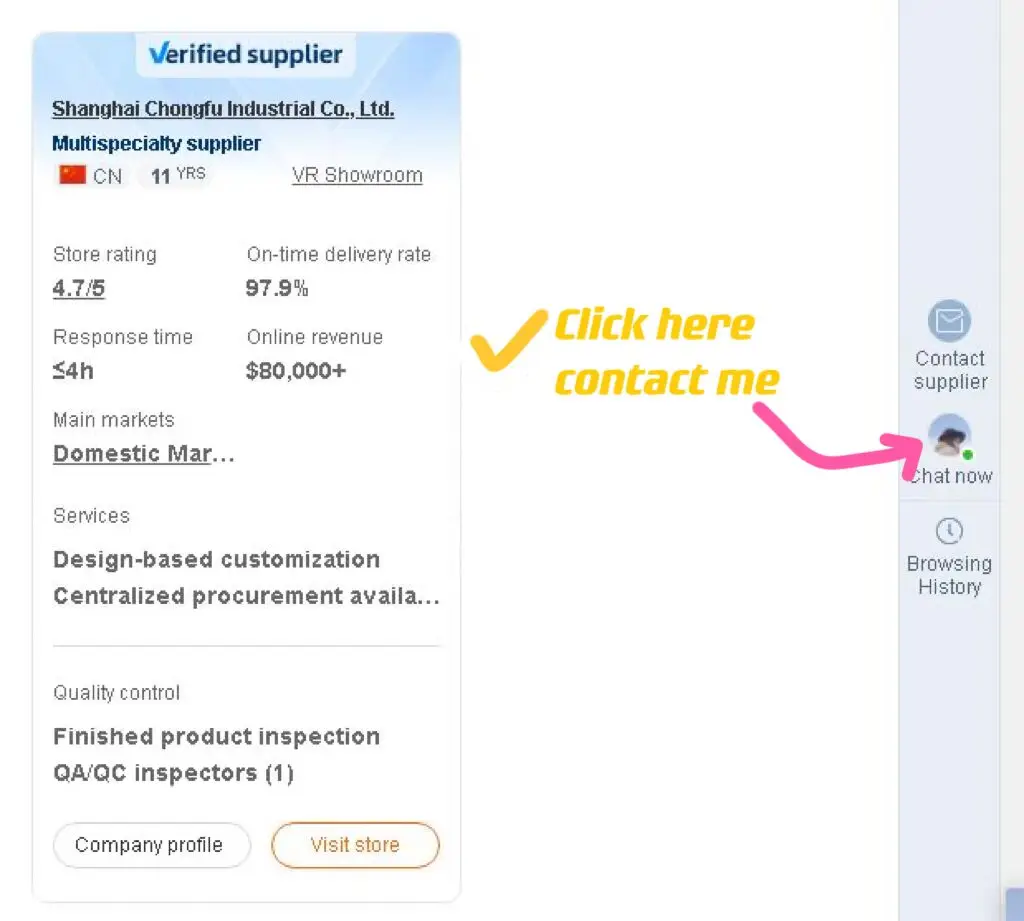

1,Are you trading company or manufacturer?

Regarding seals; We are a manufacturing factory, such as; Diaphragm, ball, ball seat, sealing ring, etc

Regarding pumps, we are a sales company and the brand of the pump; Wilden, aro, sandpiper, etc

2,What is your MOQ?

MOQ may vary by customer's special requirement; we try our best to meetyour business requirement.

3, Can you provide samples?

Of course we can, and some of them are free, but the shipping cost you need pay.

4, I have a drawing, can you produce the same?

Yes, we can produce according to the drawing requirements. It would be better if you could provide samples

5,What are you usual terms of payment?

We have many payment methods, such as;L/C,Western Union,D/P,D/A,T/T,MoneyGram

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

DE

DE

EL

EL

HI

HI

IT

IT

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

SR

SR

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

AF

AF

MS

MS

GA

GA

HY

HY

AZ

AZ

KA

KA

BN

BN

LA

LA

MN

MN

NE

NE

KK

KK

UZ

UZ

KY

KY