Benefits of Rubber Reinforced Diaphragms in Pump Applications

One more significant advantage is that rubber supported diaphragms boost the productivity of pumps. This type of diaphragm is special as it is more response than normal diaphragm that it would move liquid/air easily than before. An improved-performing diaphragm allows the pump to run better. This results in less energy consumption, thus reducing the energy bill. The introduction of λαστιχένιο δακτύλιο ροδέλας allowed the industries to have better performance at lesser cost.

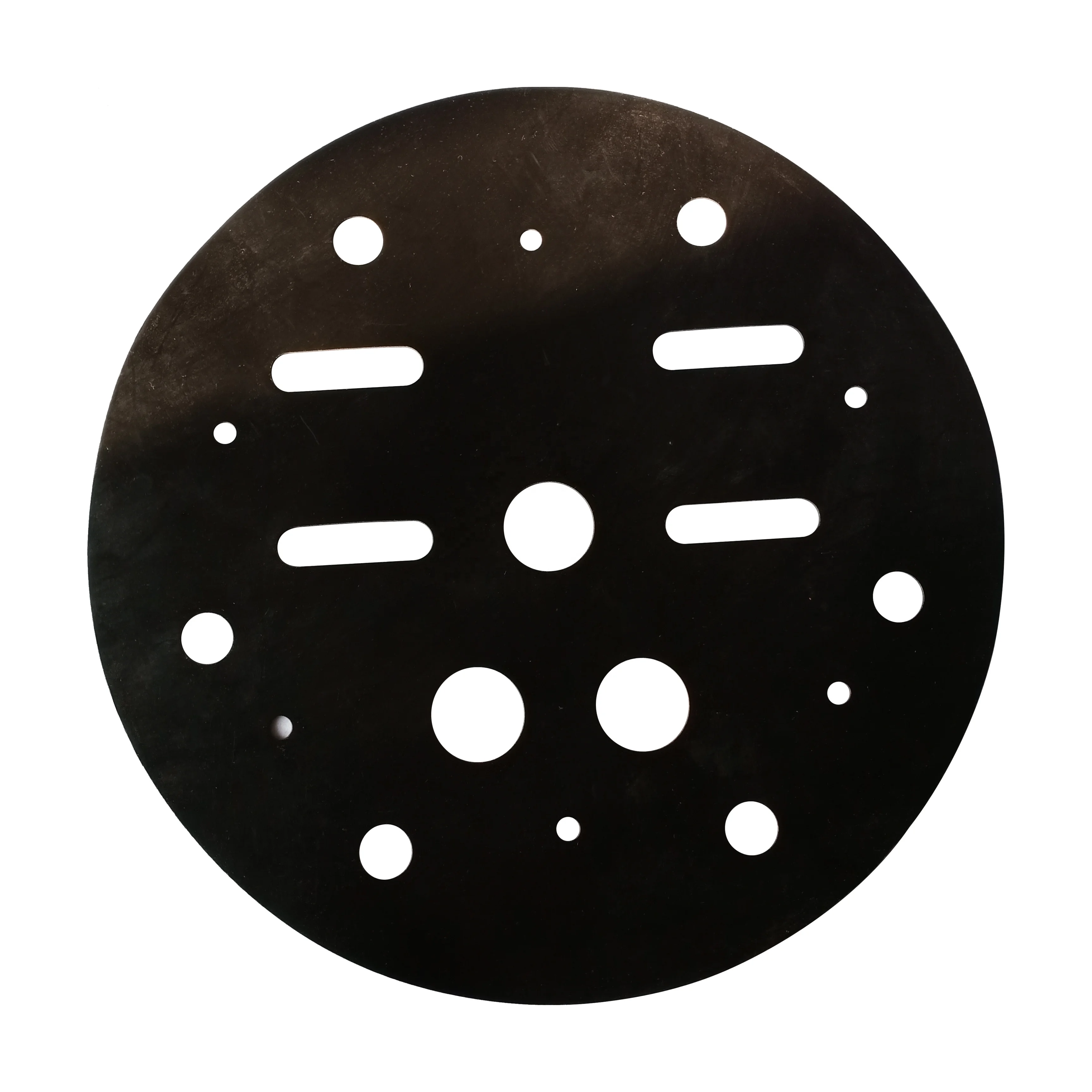

Choosing the correct type of diaphragm for each individual application is crucial for maximizing their durability. This is a feature that varies between the diverse variety of materials on the market, each with its advantages and disadvantages. For example, some diaphragms are made specifically for high pressure applications, whereas some do well in aggressive chemical environments. The use of the most appropriate diaphragm can help businesses to keep their operation up and running.

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

DE

DE

EL

EL

HI

HI

IT

IT

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

SR

SR

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

AF

AF

MS

MS

GA

GA

HY

HY

AZ

AZ

KA

KA

BN

BN

LA

LA

MN

MN

NE

NE

KK

KK

UZ

UZ

KY

KY