Πλούσια επιλογή προϊόντων

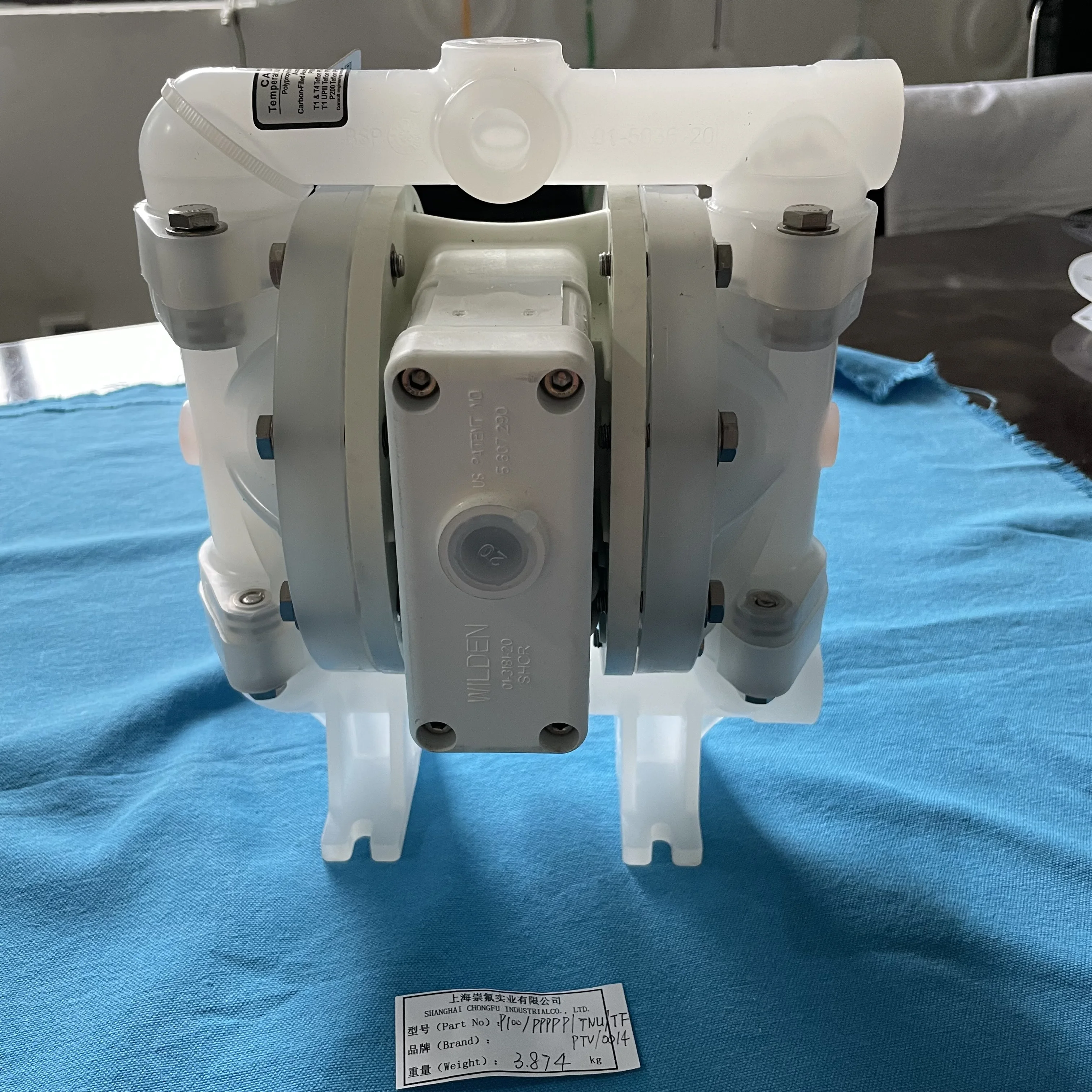

Η Shanghai Chongfu Industry Co., Ltd. προσφέρει ευρύ φάσμα διαφραγματικών πομπών και παραγωγών, συμπεριλαμβανομένων κομματιών για παγκοσμίως γνωστές μάρκες όπως Wilden, Sandpiper, Almatec, Yamada, Graco, Blagdon και Veresmatic. Το κατάλογο προϊόντων της περιλαμβάνει διάφραγματα, θέσεις τιμωμάτων, σφαιρικά τιμώματα, συνδυασμούς αεριού, κεντρικά σώματα, κελύφη, διαχειριστές, άξονες, μπάφοι και συνόλα επισκευής, προσφέροντας στους πελάτες μια εύρωστη επιλογή κομματιών και πομπών για διάφορες βιομηχανικές ανάγκες.

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

DE

DE

EL

EL

HI

HI

IT

IT

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

SR

SR

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

AF

AF

MS

MS

GA

GA

HY

HY

AZ

AZ

KA

KA

BN

BN

LA

LA

MN

MN

NE

NE

KK

KK

UZ

UZ

KY

KY

MY

MY